Origin

The TRIZ method is originally from Russia, where it was developped in the 40s’ by the inventor and author Mr. Genrich Altshuller. The abbreviation TRIZ is Russian, but can be translated in English by the (Theory of Inventive Problem Solving” (TIPS).

This approach, which can be used during a Brainstorming, can be applied in a wide range of contexts. Indeed, its creator has gathered information on the methodology used in thousands of inventions. His objective was to conceive a tool that would stimulate structured creativity when developing projects. This would help focusing precisely on the problem to be solved.

The method

Althoug te TRIZ is efficient and is carried out collaboratively, it is quite different from many other methodology, such as the 3 Disney chairs, the Mind Mapping, and so on.

In other words, the TRIZ is much more rational, and that for the following reasons : it analyses the issue by segmenting it. More specifically, it defines the contradictions of a problematic by focusing on technical parameters. This is very different from most of approaches that are based on more emotional perspectives. This means that the TRIZ narrows down the extent of developed creative ideas (even though it is still an important part of the process here as well). The reason in that when applying this technique, our focal-point to shape ideas in the final solution.

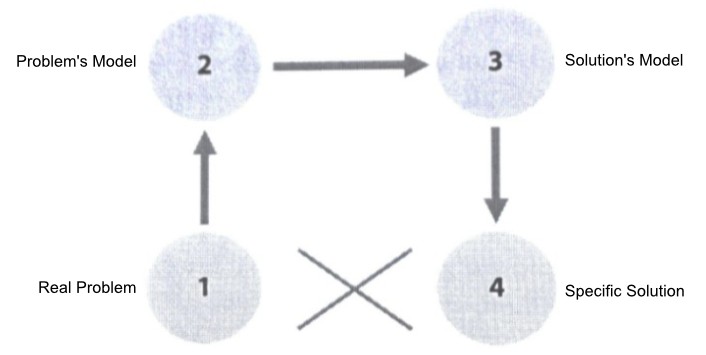

To make it simple, we can summarize the whole process into 4 basic principles, which are illustrated as followed :

First of all, you have a real problem (1) for which you need to develop a project. Before, going further, you need to define precisely the problem’s models that you want to solve (2). As soon as you have done it you can proceed to the next step, the solution’s model (3). It is between those 2 phases that you will apply the 40 innovation principles (next paragraph of this article). For the 4th stage, you analyse the solution’s model in order to create a specific answer to the issue.

40 Innovation Principles

After the models of the problematic have been decided, you will apply the 40 innovation principles of Altshuller. Don’t worry, you will not find all of them in your problem, yet at least some of them. However, going through all of them will garantee and optimal project development.

Here are the principles, including some reasoning to have :

- Segmentation : is it possible to segment the project in smaller pieces, in order to isolate the damaging element or the fondamental quality ?

- Extraction : can you extract the necessary (or interfering) element from your object / project ?

- Local Quality : Can you change the structure of the product / service on a specific point, to create the desired solution ?

- Asymmetry : Do you have the possibility to modify the product into and assymetric shape ? (and vice-versa)

- Consolidation : Are you able to assemble / combine some parts of your projects to others, allowing to create a more adapted product ?

- Universality : Is it feasible to assign more than 1 function to the same object ?

- Nesting : can your object / service be placed inside another one ?

- Counterweight : are you able to compensate the negative aspects of your projet with another product / service providing a lifting force ?

- Prior Counteraction : what bad could happen ? should counteractions be taken preliminarily ?

- Prior Action : Is it possible to avoid beforehand some negative effects that could influence the project ?

- Cushion in Advance : Can emergency measures be taken in advance, to avoid the problem ?

- Équipotentiality : should the environment of the object / service be configured to decrease its movements ?

- In Reverse : Should you consider realising a reverse action to obtain the desired result ?

- Spheroidality : Can you swap some elements or processes with other non-linear ones ?

- Dynamicity : Is it manageable to optimise some elements to make the project temporary more adapted to some specific createria ?

- Partial or Excessive Action

- Transition into a New Dimension

- Vibrations

- Periodic Action

- Continuity

- Rushing Through

- Convert Harm into Benefit

- Feedback

- Mediator

- Self-service

- Copying

- Dispose

- Replacement of Mechanical System

- Pneumatic or hydraulic

- Flexible or Thin Membranes

- Porous Material

- Changing Color

- Homogeneity

- Regection and Regeneration

- Properties Transformation

- Transition Phase

- Thermal Expansion

- Accelerated Oxidation

- Inert Environment

- Composite Materials

This technical approach has already been used by many conglomarates. Even though it might seem more adapted to use it in the industry, you could be surprised how useful it is in various fields. The real question then is not to know if the TRIZ is really efficient, instead is what are you waiting to try it ?